Precision is everything in modern manufacturing and construction. From early planning through to final fabrication, accurate data and detailed technical drawings determine whether a project runs smoothly or encounters costly delays. That’s where drone mapping in melbourne and cad drafting come together to deliver smarter, more reliable outcomes.

Drone mapping in melbourne provides highly accurate aerial data using advanced imaging and surveying technology. Instead of relying solely on manual measurements or outdated site plans, businesses can capture real-time topographical information, 3D models and site conditions quickly and safely. This level of detail ensures that designs are based on actual site conditions, not assumptions.

When this data feeds directly into cad drafting, the result is significantly improved accuracy. Designers can import mapping data into drafting software to create detailed, site-specific plans. By combining drone mapping in melbourne with cad drafting, engineers and manufacturers can identify elevation changes, access limitations and spatial constraints before fabrication begins.

One of the biggest advantages of drone mapping in melbourne is its ability to reduce risk. Inaccurate site measurements often lead to design revisions, material waste and installation delays. When aerial data is captured at the beginning of a project, cad drafting becomes far more precise. This reduces the likelihood of clashes between structural components and ensures a smoother transition from design to production.

Drone mapping in melbourne is also invaluable for large-scale or complex sites. Industrial facilities, infrastructure upgrades and commercial developments often involve challenging terrain or restricted access areas. Traditional surveying can be time-consuming and disruptive. With drone mapping in melbourne, detailed data can be collected efficiently and with minimal interruption to operations. That information then supports high-quality cad drafting that aligns perfectly with real-world conditions.

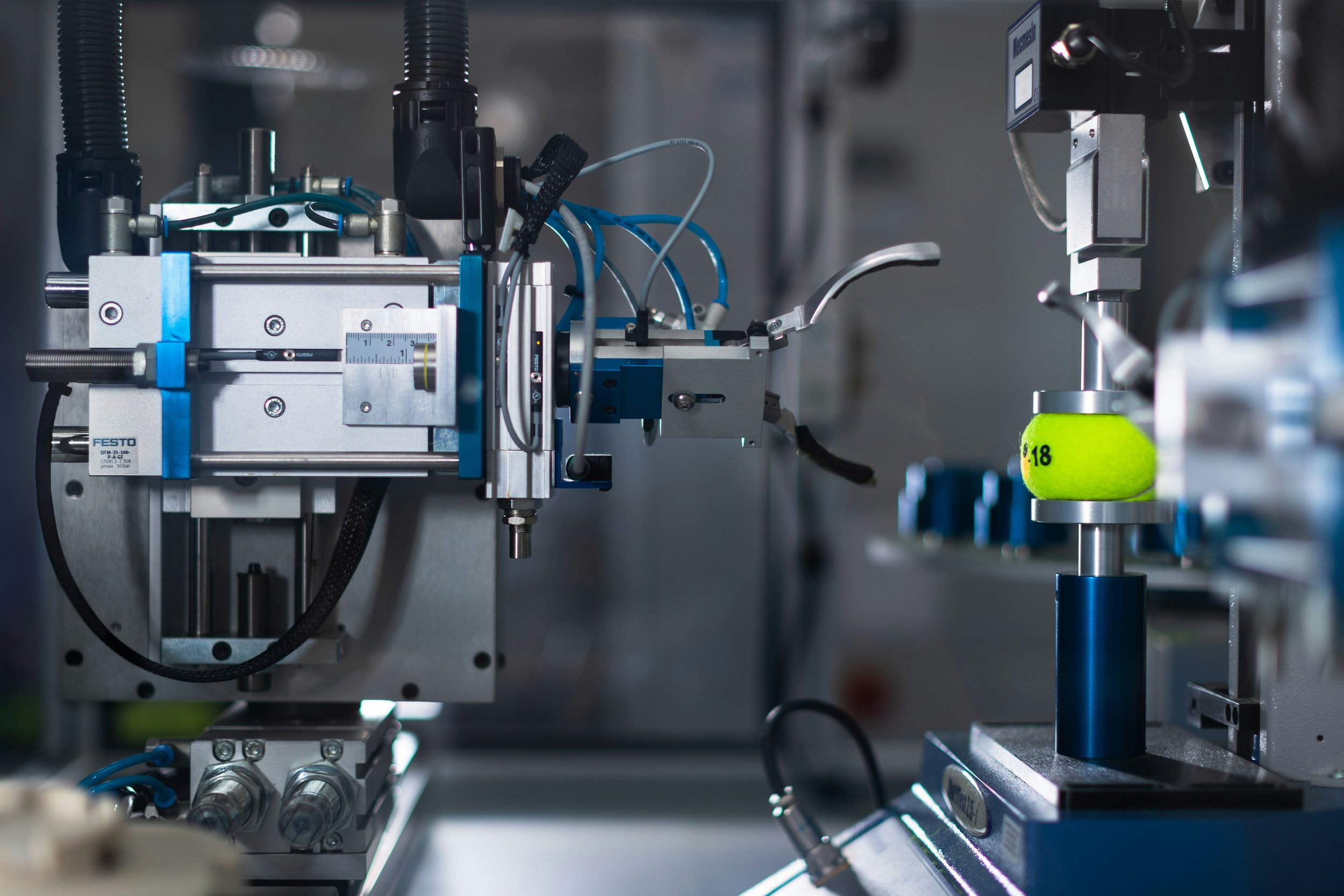

Accurate cad drafting is not just about creating drawings — it is about creating confidence. Detailed CAD files guide fabrication, machining and assembly processes. When cad drafting is informed by drone mapping in melbourne, manufacturers gain a clear understanding of dimensions, tolerances and positioning before materials are cut. This improves productivity and reduces costly rework.

Another benefit of integrating drone mapping in melbourne with cad drafting is improved communication. Clear aerial imagery combined with technical drawings allows stakeholders to visualise the project from both a macro and micro perspective. Project managers, engineers and clients can review accurate representations of the site alongside precise drafted plans, ensuring everyone is aligned from the outset.

As projects become more complex and timelines tighter, businesses cannot afford design inaccuracies. Using drone mapping in melbourne at the planning stage strengthens the entire drafting process. When paired with professional cad drafting, it creates a streamlined workflow that enhances safety, efficiency and overall project quality.

If you are planning a new development, upgrade or fabrication project, integrating drone mapping in melbourne with expert cad drafting could be the difference between costly revisions and seamless execution.

Get in touch with our team today for an obligation free quote and discover how accurate site data and precision drafting can support your next project.

contact@melbournemfg.com